- HOME

- SERVICES

- PROJECT GALLERY

- Pinnacle Apartments

- Long Bay, Auckland

- Te Wānanga o Raukawa

- Summerset Waikanae

- The Arches – Mission Bay

- 212 Apartments

- Greenview at Longbay

- Wynyard Quarter, Auckland

- One Market Lane

- Ryman Healthcare – Cambridge

- ‘The International’ – Auckland

- Design development and form models

- Shelly Bay, Wellington

- Additional Work

- SOCIAL MEDIA

3D Printing, Laser Cutting & Engraving

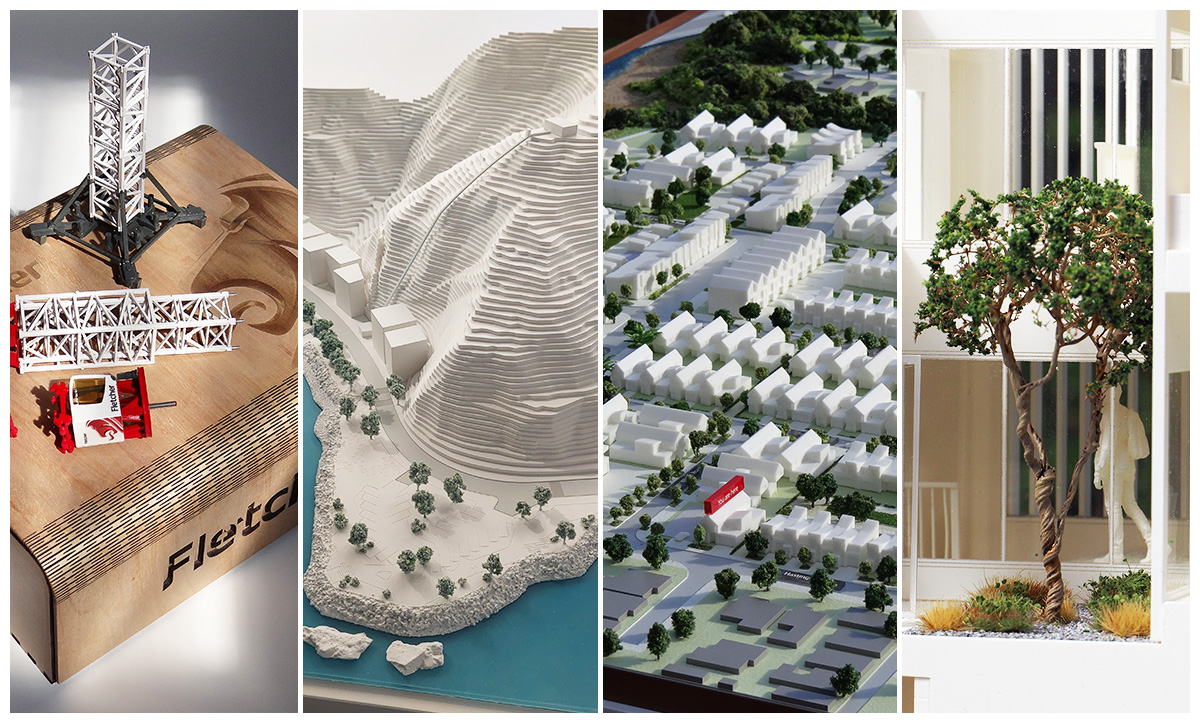

At Litchfield & Fields, we’re passionate about bringing architectural visions to life with unmatched precision and detail. Thanks to cutting-edge technologies like laser cutting and 3D printing, we’re able to take architectural model-making to a whole new level. These tools allow us to deliver models that not only look incredible but also streamline the entire production process, making things faster, more efficient, and more flexible. Here’s how we use these technologies to make your models stand out.

The Benefits of Laser Cutting in Architectural Models

Laser cutting allows us to create precise, clean-cut elements with incredible speed and accuracy. This tool is perfect for adding intricate details to your models, from detailed building façades to custom structural components.

How We Use It:

- Building Façades: Laser cutting lets us recreate complex façades with details like windows, latticework, and textures that bring your designs to life with accuracy and consistency.

- Structural Components: We craft walls, floors, roofs, and other key structural pieces efficiently, ensuring that each part is both realistic and sturdy.

- Landscaping and Surroundings: We also laser cut elements like trees, benches, and pathways, enhancing the realism of your model’s surroundings and creating a cohesive scene.

Why It’s Beneficial:

- Precision & Consistency: We achieve a level of detail that handcrafting just can’t match, ensuring quality and reliability in every piece.

- Time Efficiency: Laser cutting speeds up our workflow, allowing us to make quick adjustments when needed and deliver models on schedule.

- Material Versatility: Laser cutting works with a variety of materials, from wood and acrylic to cardboard, giving us flexibility to suit your project needs.

The Power of 3D Printing in Architectural Models

3D printing opens up a world of creative possibilities, allowing us to build highly detailed, three-dimensional elements layer-by-layer. This technology is ideal for capturing the unique shapes, textures, and features of your design.

How We Use It:

- Complex Geometries and Organic Shapes: For modern and avant-garde designs, 3D printing enables us to recreate complex shapes and curves that would be difficult to craft by hand.

- Textured Surfaces and Custom Details: Adding textures and unique details to model surfaces is easy with 3D printing, enhancing the realism and feel of architectural surfaces.

- Functional Interior Elements: From miniature furniture to custom fixtures, 3D printing lets us build interior details that help clients visualize the space more clearly.

- Modular Components: We can print modular parts, making it easy to create scalable models or add removable elements, allowing for dynamic presentations.

Why It’s Beneficial:

- Creative Freedom: 3D printing lets us experiment with new shapes and textures, giving us the flexibility to push design boundaries.

- Rapid Prototyping: We can make changes digitally and reprint quickly, so the design process remains flexible and adaptive.

- Enhanced Realism: With fine details like furniture and textures, your model comes to life, giving clients a compelling and accurate view of the space.

The Power of Combining Laser Cutting and 3D Printing

By blending laser cutting and 3D printing, we bring out the best of both technologies. Laser cutting provides a solid foundation for flat structural elements, while 3D printing adds depth, intricacy, and functionality for components requiring more dimension and detail.

How We Combine Them:

- Hybrid Structures: We use laser-cut materials for the building’s main structure, then add 3D-printed parts for customized details, textures, or functional elements.

- Unique Presentation Models: A mix of materials and textures makes our models visually stunning and memorable, showing off every aspect of your project’s design.

- Efficient Iterative Prototyping: With in-house laser cutting and 3D printing, we can quickly make adjustments, keeping the model-making process flexible and responsive to changes.

Why Litchfield & Fields?

For us at Litchfield & Fields, laser cutting and 3D printing are about more than just efficiency—they’re about enhancing the quality and craftsmanship of our work. These technologies give us a clear edge, helping us create models that are stunningly detailed and highly realistic. Whether you need a high-impact presentation model or a detailed prototype, we’re here to make sure every part of your vision is represented beautifully.

With laser cutting and 3D printing, we’re able to focus on what matters most—delivering models that inspire, impress, and bring your architectural ideas to life.

Contact us to discuss your model making ideas.